Hartle were asked to supply their services by McLaren Construction Ltd., a company specialising in construction, property and interior design. This project entailed contributing to the Magna International project which consisted of the construction of a 225,000 square feet building for an aluminium casting facility, which makes parts for Jaguar Land Rover. Aluminum Casting is a process that essentially forms aluminum into different products, such as car engines.

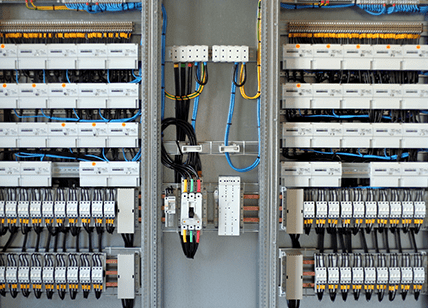

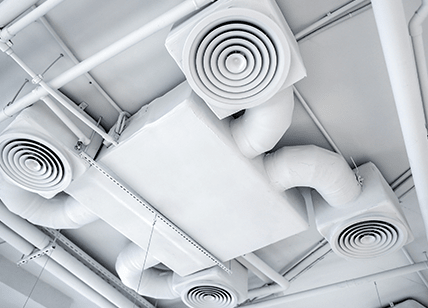

Hartle supplied mechanical and electrical services to the foundry and office complex. This included air conditioning throughout, supplying hot and cold water systems, ventilation, a low pressure water heating system served via a medium water pressure heating system, and above ground drainage to remove soil, waste and water.

The foundry also required a displacement ventilation system, where conditioned outdoor air is supplied at a low velocity from air supply diffusers located near floor level and extracted above, usually at ceiling height; and a base fit-out for all service pipework which included a medium water pressure heating system, cooling water, vacuum compressed air, and Nitrogen and oil lines, ensuring machinery and equipment could run smoothly and efficiently.